Problem statement

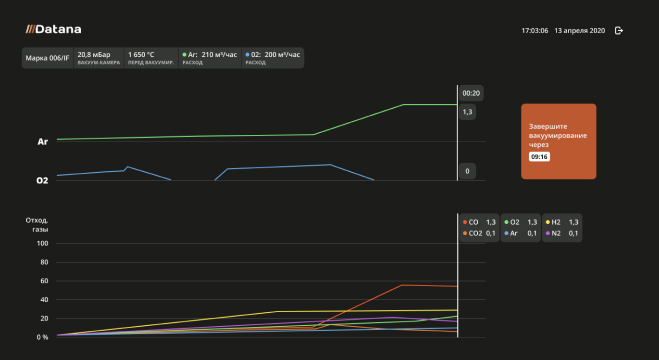

- The absence of immidiate information about the process

- Hight degree of human factor influence leads to the overconsumtion of material, technical and power resources and productivity reduction

Solution

- Recommendations for the change of vacuuming parameters are formed

- Allows predictions of the production process at the current vacuuming parameters

Effects

Reduction of vacuum treatment process duration

Reduction of material, technical and power resources

Other Solutions

Ladle skimming monitoring at hot metal desulphurization plant

ABOUTEffects

- Reduction of reagent consumption

- Reduction of Sulphur content in the metal

Ladle slag detection

ABOUTEffects

- Guarantees the specified product quality

- Reducion sorting of metal

- Reduction the total amount of scrap

Slag detection at BOF/EAF

ABOUTEffects

- Reduction of the consumption of ferroalloys and deoxidizers

- Reducing the duration of secondary treatment

- Increasing the quality of metal

- Reduction of electricity consumption