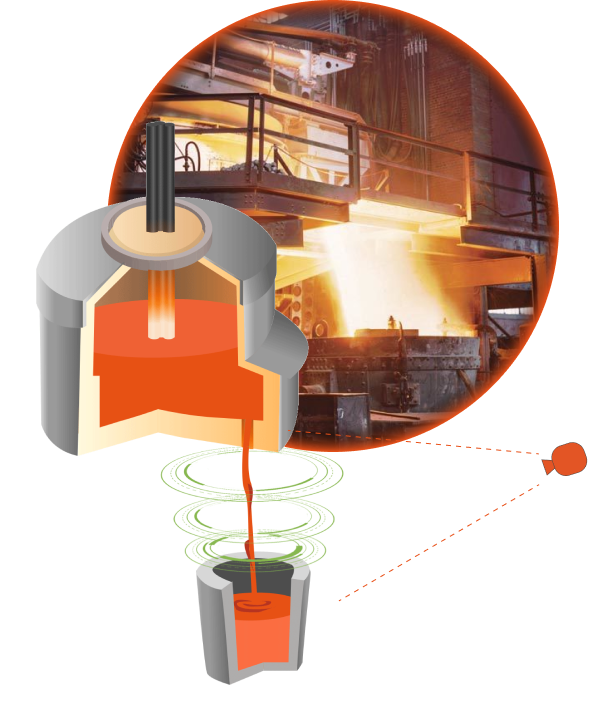

BOF EAF

Problem statement

- Slag gets into the ladle during metal tapping

- Human error is a common cause of an accident

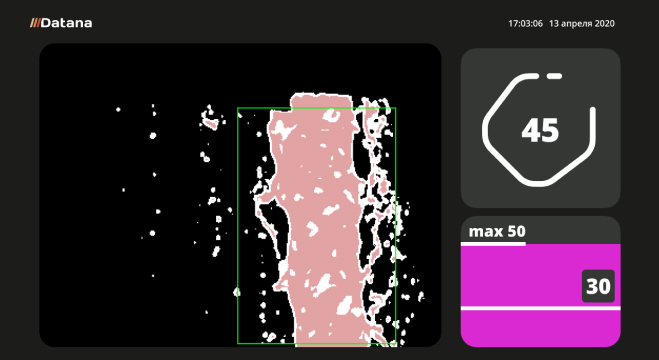

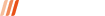

Solution

- Recommendations are created in real time "Change the angle (EAF/BOF)", if the ratio metal/slag is higher or equal to the limit value

- Assessment of metal presence in a flow

Effects

Reduction of the consuption of ferrolloys and dexidizers

Reducing the duration of secondary treatment

Increasing the quality of metal

Other Solutions

Optimisation of decarburization process at the vacuum degasser

ABOUTEffects

- Reduction of vacuum treatment process duration

- Reduction of material, technical and power resources

Metal temperature prediction model for steel-pouring and tundish ladles

ABOUTEffects

- Reduction of electrode and electric power supply consumption at the ladle furnace

Camera-based control of ladle stirring

ABOUTEffects

- Reduction of argon consumption

- Reducing the electricity consumption

- Increasing the production safety

- Increasing the quality of the end product