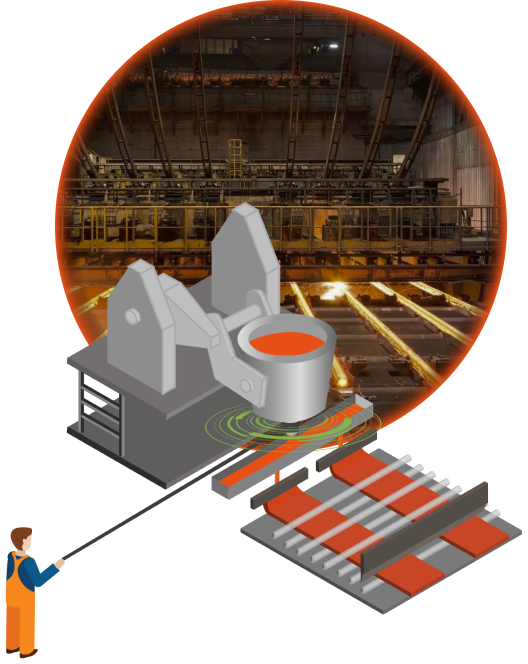

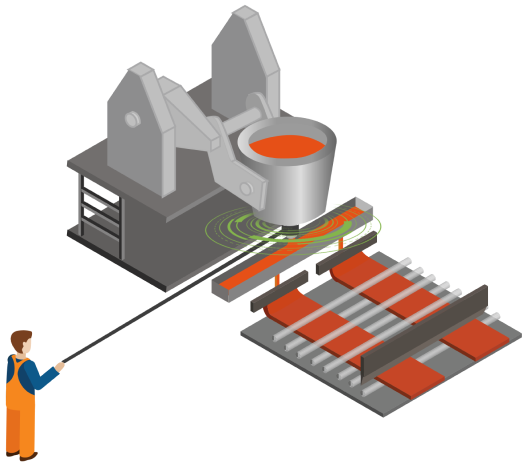

Problem statement

- Premature closing of the slide gate leads to excessive residue of metal in the ladle and losses

- In case of later closing of the slide gate, slag gets into the continuously cast billet which leads to the reduction of metal quality

Solution

- Give recommendations to the operator about the necessity to close the slide gate earlier taking into account operator reaction time and the time when the slide gate activates

- Automatic closing mode for the slide gate is foreseen

Effects

Guarantee of the specified product quality

Reduction of metal sorting

Reducing the total amount of scrap

Other Solutions

Ladle skimming monitoring at hot metal desulphurization plant

ABOUTEffects

- Reduction of reagent consumption

- Reduction of Sulphur content in the metal

Optimisation of decarburization process at the vacuum degasser

ABOUTEffects

- Reduction of vacuum treatment process duration

- Reduction of material, technical and power resources

Slag detection at BOF/EAF

ABOUTEffects

- Reduction of the consumption of ferroalloys and deoxidizers

- Reducing the duration of secondary treatment

- Increasing the quality of metal

- Reduction of electricity consumption