Problem statement

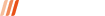

- Ordering temperature may be done with obvious excess in order to reduce the risk of the metal cooling down. This approach leads to the increase in the consumption of electrical power supply and graphitized electrodes.

Consequences:

- There are emergencies

- The lining resource is not fully developed

Solution

- The temperature order can be made with a deliberate excess in order to reduce the risk of metal cooling. This approach leads to an increase in the consumption of electricity and graphite electrodes.

Effects

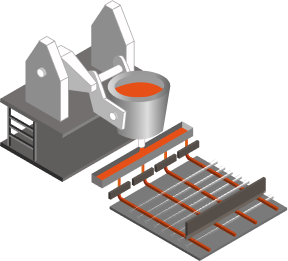

Reduction of electrode and electric power supply consumption at the ladle furnace

Заказ температуры на МНЛЗ

Прогноз температуры в стальковше и промковше

- Температура ликвидуса

- Перегрев металла в промковше над температурой ликвидус

- Добавление

материалов - Продувка

аргоном - Температурно-скоростные

режимы предыдущей плавки

Сбор и анализ данных

Оборот стальковша

Выпуск

Внепечная

обработка

обработка

Разливка

- Нагрев

- Стойкость

футеровки

- Температура ликвидуса

- Перегрев металла в промковше над температурой ликвидус

Прогноз температуры в стальковше и промковше

Оборот стальковша

Выпуск

Внепечная

обработка

обработка

Разливка

Сбор и анализ данных

Заказ температуры на МНЛЗ

Other Solutions

Optimisation of decarburization process at the vacuum degasser

ABOUTEffects

- Reduction of vacuum treatment process duration

- Reduction of material, technical and power resources

Ladle skimming monitoring at hot metal desulphurization plant

ABOUTEffects

- Reduction of reagent consumption

- Reduction of Sulphur content in the metal

Camera-based control of ladle stirring

ABOUTEffects

- Reduction of argon consumption

- Reducing the electricity consumption

- Increasing the production safety

- Increasing the quality of the end product