Problem statement

-

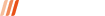

The lining of furnances steel ladles "works" in extreme thermal and mechanical conditions. The risk of masonry burnout is high

-

The technical condition of the lining is assenssed by the personnel

-

Human error is a common cause of an accident

Consequences:

- There are emergencies happens

- The lining resource is not fully developed

Solution

-

Reduces the influence of the human factor

-

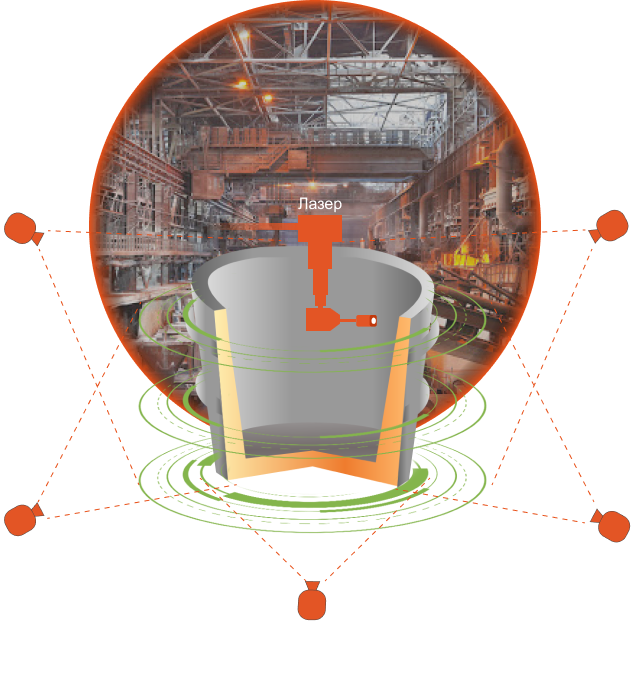

Gives an objective assessment of the technical condition

-

Helps in decision making

-

Generates the thermal profile of the object and detects anomalies

-

Performs scanning, analysis of the lining and the parameters affecting it and predicts the remaining life (wear condition prediction module)

Effects

Other Solutions

Ladle skimming monitoring at hot metal desulphurization plant

ABOUTEffects

- Reduction of reagent consumption

- Reduction of Sulphur content in the metal

Slag detection at BOF/EAF

ABOUTEffects

- Reduction of the consumption of ferroalloys and deoxidizers

- Reducing the duration of secondary treatment

- Increasing the quality of metal

- Reduction of electricity consumption

Camera-based control of ladle stirring

ABOUTEffects

- Reduction of argon consumption

- Reducing the electricity consumption

- Increasing the production safety

- Increasing the quality of the end product