Knowledge acquisition

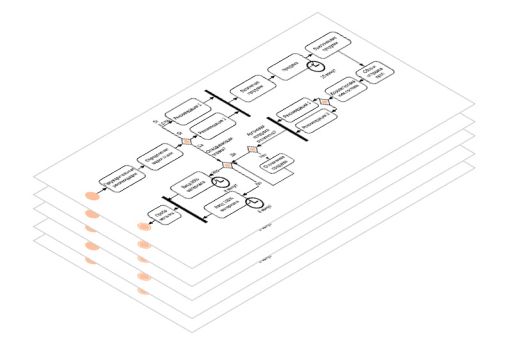

The process of knowledge filling is carried out together by experts and knowledge engineers through the knowledge database building (“digitalization” of technology).

Performs continuous process analysis, and in case of process conditions disturbances recommendations on corrective measures implementation are provided, that will allow to increase machine operational consistency, process efficiency and to decrease operational costs.

The process of knowledge filling is carried out together by experts and knowledge engineers through the knowledge database building (“digitalization” of technology).

The knowledge database is an immediate reference tool that the operator reaches to during production. The system continuously analyzes the process. If the operating practice is violated, the system provides recommendations. This allow to improve process consistency and reduce costs.

For production development modules for simulation modelling, collection and analysis of statistics are introduced into the system. Based on the acquired data, experts can develop new technologies.

Production audit, target definition, tasks setting

Collection and analysis of the historical data

Models adjustment, interface adjustment

Tests, cost-benefit analysis

Additional functional capabilities

Integration with Automated System Control and controllers

Has been implemented